High-Performance Engineering Plastic Material Sealing Component Solutions

We specialize in the mixing and molding of high-grade composite sealing materials such as PTFE, PCTFE, PI, PEEK, FFKM, PVDF, etc., and provide one-stop integrated services of high-quality key sealing parts, auxiliary design evaluation and precision manufacturing; so that you can have a wide range of high-efficiency sealing components such as O-rings, gaskets, valves and other components specially designed to solve your problem orientation, and comprehensively optimize the performance of your equipment and products.".

High performance

Engineering Plastic Sealing Components

Solution

We specialize in the mixing and molding of high-grade composite sealing materials such as PTFE, PCTFE, PI, PEEK, FFKM, PVDF, etc., and provide one-stop integrated services of high-quality key sealing parts, auxiliary design evaluation and precision manufacturing; so that you can have a wide range of high-efficiency sealing components such as O-rings, gaskets, valves and other components specially designed to solve your problem orientation, and comprehensively optimize the performance of your equipment and products.".

Will your seals

Extreme Environment Failure

?

Frequent equipment shutdowns causing significant losses?

Is the sealing material unable to resist chemical corrosion?

Are seals failing or components requiring frequent replacement in extreme temperature environments, potentially impacting product yield?

Let Chengxin Industrial Seal King Let me help you.

Choose Chengxin, say goodbye to frequent downtime and wear and tear.

!

Chengxin Gao Engineering Plastic Seal King

Six Core Advantages

Facing demanding industrial challenges, Chengxin delivers exceptional solutions through six core strengths. Beyond providing premium materials, we integrate rapid response mechanisms, customized designs, and expert technical support to ensure your equipment maintains peak performance in any extreme environment. This significantly reduces downtime risks and boosts production efficiency.

Premium Material Blend

Precision machining capabilities

Professional Technical Support

100% Yield Capability

Quality Assurance System

Custom orders are available from one to one million units.

Six Major High performance Material Combination

Polyimide (PI)

Polyvinylidene fluoride (PVDF)

Polychlorotrifluoroethylene (PCTFE)

Polyetheretherketone (PEEK)

Polytetrafluoroethylene (PTFE)

Perfluoroelastomer (FFKM)

Delivery Materials Checklist

01.

Bars

Multiple diameters and lengths to meet machining requirements.

02.

Sheet material

Available in multiple thicknesses and sizes, suitable for cutting and forming.

03.

Pipe

Various inner and outer diameters for fluid transmission and protection.

04.

Molded parts

Custom-made to design specifications, precision-formed.

Chengxin's Four Major Industrial Sealing Components

Solution

Chengxin Sealing King provides one-stop solutions for mass production of components, resolving product and equipment issues.

Chengxin Sealing King leverages its leading technology and extensive experience to provide diverse customized sealing solutions for various industries. Below is a showcase of our key product portfolio across different application fields, including sealing components belonging to the following four major sets, ensuring equipment operates efficiently and stably even in the most demanding environments.

Spring-Assisted Sealing Assembly

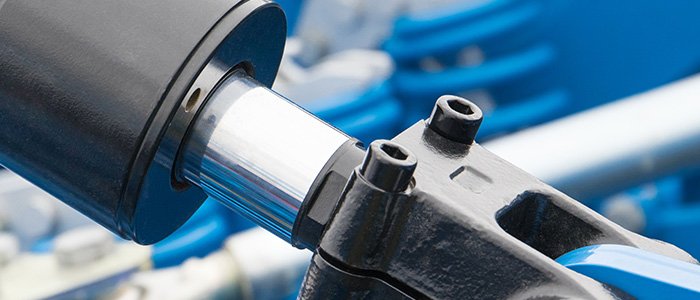

Hydraulic Cylinder Seal Kit (Reciprocating)

Static Flange/Valve Sealing

Sanitation/Chemical Engineering/Vacuum and External Protection

Solve Your Industry's Sealing Challenges

Chengxin Industrial Sealing King not only provides high-performance materials but also delivers professional solutions to help you overcome the most demanding industrial environments. We ensure your equipment operates reliably under high temperatures, high pressures, and corrosive media, significantly improving product yield and extending equipment lifespan.

Overcoming Extreme Temperatures

Resist corrosion

Improve equipment yield

Extend product lifespan

Industrial Application Fields

Semiconductor Manufacturing

Chemical Process

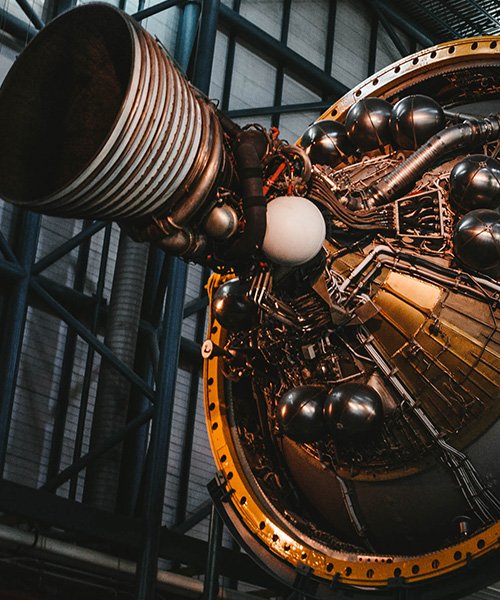

Aerospace Industry

Pharmaceutical and Biotechnology

Oil and Natural Gas

Food Processing

Success Stories Showcase

For years, we have assisted numerous leading enterprises in resolving critical sealing and component challenges, significantly enhancing equipment reliability, reducing maintenance costs, and improving process efficiency. Below are results from some representative projects.

Reduced downtime

Extended service life

Improvement in Process Yield

Annual Cost Savings

Technical Support and Service Commitment

Comprehensive technical support

- 24/7 Technical Support Hotline Service

- On-site Application Engineer Support

- Failure Analysis and Root Cause Investigation

- Customized Training Courses

- Recommendations for Material and Process Optimization

- Long-term technical partnership

Our technical team comprises seasoned materials engineers, mechanical engineers, and application specialists with over 20 years of combined industry experience. Whether addressing urgent technical issues or executing long-term optimization projects, we deliver professional, timely, and effective support.

Quality Assurance Commitment

- ISO 9001 Quality Management System

- 100% Product Inspection and Traceability

- Complete Material Certification and Test Reports

- Compliant with RoHS and REACH regulations

- Periodic Customer Satisfaction Survey

- Continuous Improvement and Innovation Mechanism

Customer Testimonials

Over the past three years of collaboration with your company, the reliability of our equipment has significantly improved. The performance of FFKM seals in extreme chemical environments has far exceeded expectations, and the technical team's professional support has been impeccable. This is a partner who truly understands customer needs.

Manager Li

Equipment Engineering Department A Well-Known Semiconductor Equipment Manufacturer

Facing complex chemical process challenges, they not only provided high-performance PVDF solutions but also helped us optimize the entire system design through failure analysis. Professional, responsive, and reliable—they are our most trusted technical partner.

Chief Engineer Zhang

Process Technology Center Major Petrochemical Group

From material selection to on-site installation guidance, comprehensive technical support ensured the smooth completion of our project. The machining precision and consistent quality of the PEEK components were impressive, significantly reducing our equipment commissioning time.

Director Wang

Aerospace Components Supplier Research and Development Department

Start your project now

Your equipment deserves the most advanced sealing solutions. By choosing Chengxin Seal King, you will achieve:Significantly improved yield rates, substantially reduced downtime, effectively lowered maintenance costs, and comprehensively enhanced production efficiency.Contact Chengxin's expert team immediately. Let us work together to tailor solutions that ensure your critical applications operate efficiently and reliably even in the harshest environments, propelling your innovation and productivity to new heights!

Frequently Asked Questions

How to choose the most suitable material?

Material selection requires consideration of multiple factors including operating temperature, pressure, chemical media, and motion characteristics. Our application engineers will recommend the most suitable material solution based on your specific requirements, leveraging our material database and application expertise. When necessary, material compatibility testing and performance validation can be conducted to ensure the reliability of the selected materials.

How long is the delivery time?

Standard products typically ship within 3-5 business days, while custom machined parts require 7-15 business days depending on complexity. Rush orders can be expedited through our fast-track service for delivery within 48-72 hours. We understand the stringent delivery requirements of the manufacturing industry and will fully accommodate your production scheduling needs.

Do you provide sample testing?

Yes, we provide complimentary samples for customers to conduct preliminary testing and evaluation. For large-scale projects or long-term collaborations, we also support on-site trials and performance verification to ensure the product performs as expected under actual operating conditions, thereby reducing procurement risks.

Does the product come with a warranty?

All products come with a comprehensive quality guarantee, including Certificates of Conformity (COC), dimensional inspection reports, and performance test data. They comply with relevant industry standards and customer specifications. Should any losses occur due to product quality issues, we assume corresponding responsibility and provide solutions.

Can you provide technical training?

How to handle failure issues?

How to choose the most suitable material?

Material selection requires consideration of multiple factors including operating temperature, pressure, chemical media, and motion characteristics. Our application engineers will recommend the most suitable material solution based on your specific requirements, leveraging our material database and application expertise. When necessary, material compatibility testing and performance validation can be conducted to ensure the reliability of the selected materials.